Swiss-Turn Gang tool type ML205

Tooling Zone

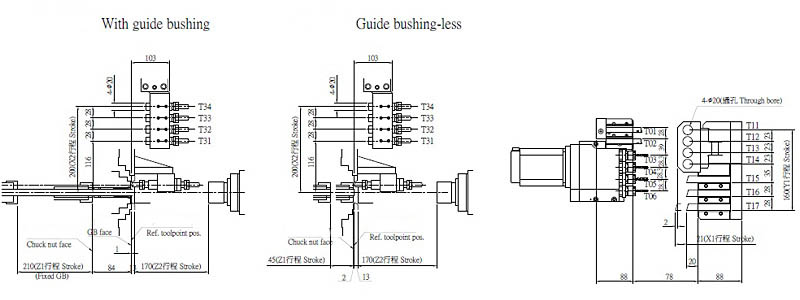

Standard machine tool post layout

ML-205-II

Machining capacity

Main spindle Bar stock diameter

3~20 mm

Max.sub spindle bar capacity

20 mm

Max. machining length

170 mm ( Direct motor - driven guide bushing )

80 mm ( Mechanical-drive guide bushing )

210 mm ( Fixed guide bushing )

45 mm ( without Guide bushing)Max. main spindle drilling / tapping diameter

∮10 mm / M10

Max. sub spindle drilling / tapping diameter

∮8 mm / M8

Max. drilling / tapping dia. of radial live tooling device

∮6 mm / M5

Max. mountable slitting saw dia. / Nos. at cross tool post

∮30 mm × 2

Max. drilling / tapping diameter of sub spindle tools

∮6 mm / M5

Machine Capacity

RPM

Main spindle

200∼10,000 (※1)

Sub spindle

200∼12,000 (※2)

Radial live tooling

200∼5,000

Sub spindle live tooling

5,000

Tool numbers : 21

OD turn tool (left)

2

OD turn tool (right)

3

Axial static tool

4

Sub spindle axial static tool

4 ( mounted at face / back ID tool post) + 2 ( mounted at independent back tool post)

Radial live tooling

4

Sub spindle live tooling

2

Tool size

OD turn tool shank

12 × 12 × 85 mm

Boring tool shank ( for face / back, back tool post )

∮20 mm

Collet for radial live tooling

ER11× 2 / ER16× 2

Collet for sub spindle live tooling

ER11× 2

Rapid traverse

32 M / Min (X: 24 M / Min)

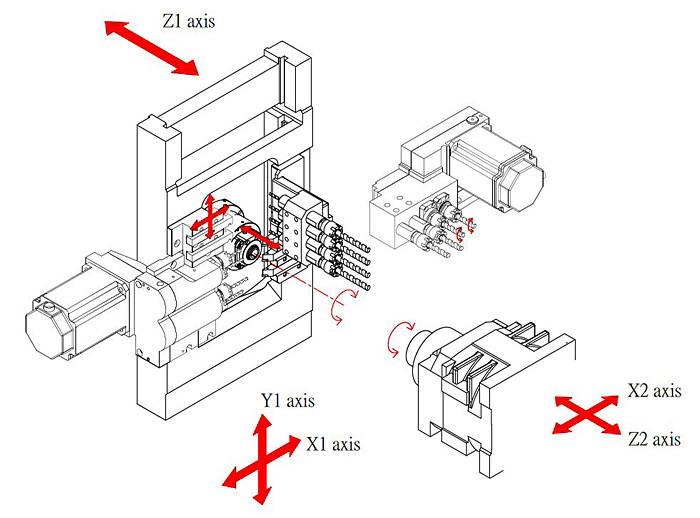

Controlled axes

5 (X1、Y1、Z1、X2、Z2)

Main spindle motor

2.2 / 3.7 KW

Back spindle motor

1.5 / 2.2 KW

X1、Y1、Z1、X2、Z2 Axes motor

0.5 KW

Radial live tooling motor

0.75 KW

Sub spindle live tooling motor

0.5KW

Coolant pump motor

0.75 KW

Lubrication pump motor

11W( 0.011KW)

Spindle oil Cciller pump motor

0.19 KW

Others

Machine weight

1,700 Kgs

Equipment capacity

11 KVA

Power source required

≧9 KVA

Air pressure

≧0.4 MPa (Kg / cm2 )

Air flow

≧30 NL / min

Coolant tank capacity

115L

Machine size : L×W×H

1,640 × 1,080 × 1,700 mm

※ 1 : Normal / limited main spindle speed is 6,000 / 8,000rpm when mechanical-drive rotary guide bushing is used.

※ 2: RPM should be limited to 10,000rpm when front part catcher unit is mounted。

Standard NC Specification:

No. of controlled axes

5 (X1,Z1,Y1,X2,Z2)

Spindles synchronized (speed & phase angle)

S1- S2 ( Main spindle -Sub spindle)

Axes synchronized

Z1-Z2

Axes composite control

Z1-Z2

Axes simultaneously controlled

Max. 4 axes / each path

Mini. input increment

0.001mm ( Diametrical designation for X axes)

Mini. command increment

X axes : 0.0005 mm / Other axes : 0.001 mm

Max. programmable digits

± 8 digits

Rapid traverse rate

32M / Min (X1: 24 M / Min)

Spindle / Feed rate override

0∼150% / 10% incremental

Absolute / incremental command

X,Y,Z: Absolute / U,V,W Incremental

Tool offset capacity

±6 digits / 64 pairs

Display unit

10.4"color LCD

Program storage capacity (S1+S2)

1 Mbyte (equivalent to 2,560 m tape)

Programs stored quantity (S1+S2)

800

Standard accessories & software:

Automatic programming software

Tool-tip height compensation software

Tool life management

Periodic maintenance screen

Main spindle collet sleeve (for round bar machining)

Sub spindle collet sleeve (for round bar machining)

Door interlock

Coolant flow switch

Spindle oil chiller device

Standard tool kit

Axis fixer block (avoid axes moving during transit)

Auto power off

Face / back ID tool post

4-spindle cross tool attachment (※1)

Back tool post ( with 2 fixed tools, 2 live tools) (※2)

Cutting coolant nozzles in tool holder

3 color working light

Working lamp

Coolant pump ( 0.75KW)

Parts catcher

Manual pulse generator (MPG hand wheel)

Bar feeder interface